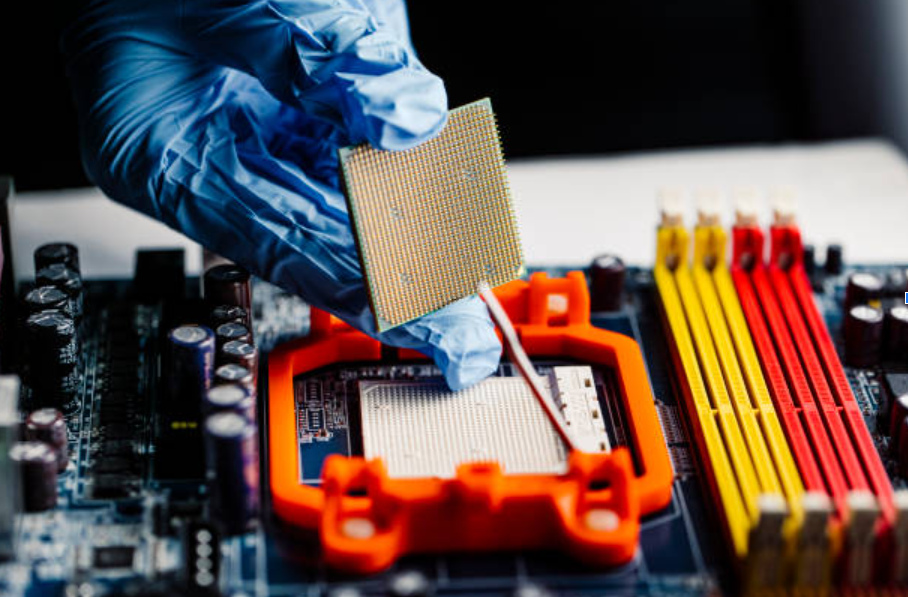

Why Circuit Protection Is Critical in Electronics Design

In the world of electronics, safety, reliability, and longevity are essential qualities that engineers must consider from the earliest stages of product design. One of the key strategies for achieving these goals is the use of circuit protection components. These devices safeguard electronic systems from common hazards like voltage spikes, current surges, electrostatic discharge (ESD), and short circuits. Without adequate protection, sensitive components can suffer irreversible damage, leading to device failure, financial loss, or even safety hazards.

The Role of Circuit Protection in Modern Electronics

With the tendency of electronic gears to be lighter and more sophisticated, the corresponding need for circuit protection components for these devices is much higher. Every day, electronics usually come with microcontrollers, wi-fi, and very fragile sensors that are prone to unexpected power surges and electrical noise. It is a must for every circuit designer, whether it is for a smartphone, industrial control device, or automotive ECU, to take care of the shielding of their circuits from electrical interferences that may cause immediate or long-term damage.

The circuit protection principle is not only related to the prevention of dead time failure, but also the increase of device lifespan, drops in, maintenance cost, and Greater reliability. In commercial and industrial applications, equipment being out of order can mean huge losses in productivity. The installation of circuit protection brings it to a great extent, close to zero.

Common Types of Circuit Protection Components

There are many types of circuit protection components, each designed to guard against specific electrical threats. Fuses and circuit breakers protect against overcurrent conditions by interrupting the circuit when excessive current flows. Metal oxide varistors (MOVs) and transient voltage suppression (TVS) diodes protect against voltage spikes by clamping excess voltage to safe levels.

Other passive circuit elements, such as thermistors, take care of inrush current, while ESD protection diodes are the watchdogs that alert against electrostatic discharges, which, otherwise, would destroy integrated circuits. These discrete parts contribute uniquely to the attainment of circuit fidelity and to the assurance of safe operation in diverse environments.

See also: Audio Delay in YouTube Videos? These Earbuds Fix That

Applications That Demand Robust Circuit Protection

While practically every electronic application can derive benefits from circuit protection components, few Applications can do it more than others. In consumer electronics such as cellphones, tablets, and notebooks, protection is imperative so as to avoid harm from power fluctuations and static electricity. They are often used in environments that are different, are frequently changed, and are recently charged by different sources that, in turn, increase the likelihood of electrical issues.

In industrial workplaces, motors, relays, and power supplies produce electromagnetic interference and spikes that may disrupt control circuits. In this case, protection devices act as a shield for the control logic against the high-power switching transients. Likewise, in the automotive sector, voltage spikes resulting from inductive loads such as fuel injectors and fans occur; thus, protection is required to adhere to strict standards for safety and performance.

The Cost of Neglecting Circuit Protection

Overlooking the use of circuit protection components might have serious repercussions. At a minimum, an unprotected circuit could suffer from transient and temporary circuit operation or could even shorten the life span of the entire device. However, the disaster could be the opposite of these two, with the full breakdown of the system, loss of data, and safety hazards like overheating or fire.

In the case of regulated industries such as those in medical devices, aerospace, or automotive, the absence of an appropriate circuit protection could directly lead to issues with standard safety, loss of product, and even legal responsibilities. Such risks are way higher than the small cost that would have been incurred on the design of appropriate protection from the start.

Choosing the Right Protection Method

Successful performance of circuit protection components comes with a deliberate strategy. Designers must first consider what types of risks their devices are likely to face; these include overvoltage, overcurrent, electrostatic discharge (ESD), or thermal overload. They then have to choose appropriate protection means. This process involves selecting components that have the right ratings, times of response, and are compatible with the surrounding circuitry.

A good protection strategy is also based on layering the multiple components that address the various threats. For instance, within a system, there might be a fuse for current protection, a TVS diode for voltage spikes, and an ESD diode for human-touch interfaces. Components that are sourced from trusted manufacturers assure high and uniform quality, accurate specifications, and also provide support for design integration.

Compliance and Safety Standards

Many firms look into electrical safety when setting their standards; for instance, IEC, UL, and ISO certifications, to mention a few. These standards dictate the use of proven circuit protection components that are certified and tested. For a product to meet the regulatory requirements right from the beginning, it must be designed without expensive reworks and be expedited to the market faster.

In global markets, compliance with international safety standards can be a stronger advantage than a selling point. Also, products which, on the whole, protect and are safe, a lot are more likely to gain trust from users and pass through the regulatory checks more smoothly.

Final Remarks

The inclusion of circuit protection components in the design of electronics is not a matter of option. They are achieving this goal by being the first line of defense against electrical disturbances, thus enabling even delicate electronics to operate in the manner envisaged by the designer. Proper circuit protection is, furthermore, a key investment for the quality of products and a sense of peace, as it is true for devices that range from everyday gadgets to critical industrial systems.