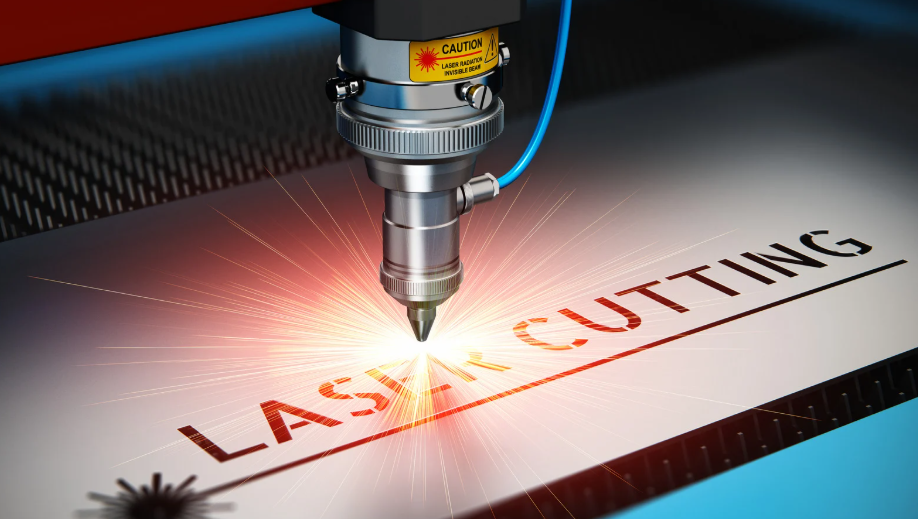

The Role of Laser Cutter Fume Extractors in High-Precision Manufacturing

In high-precision manufacturing, laser cutting has become a cornerstone for producing intricate designs with exceptional accuracy. However, the process generates hazardous fumes that can compromise air quality and reduce machine efficiency. Installing a laser cutter fume extractor not only ensures cleaner air but also promotes productivity and protects sensitive equipment from particulate buildup during operation. In environments where precision and consistency are paramount, effective fume extraction is a critical component of operational excellence.

Understanding the Hazards of Laser Cutting Emissions

Laser cutting involves intense heat that vaporizes materials such as plastics, metals, and composites. This reaction releases microscopic particulates and volatile organic compounds into the air. These emissions are not merely unpleasant—they are toxic and potentially combustible. Without proper extraction, airborne contaminants can accumulate, leading to respiratory health risks and machine malfunction.

Creating a safe working environment means capturing these fumes at the source. The effectiveness of an extraction system directly impacts both employee safety and manufacturing outcomes.

The Science Behind Fume Capture

When laser cutting occurs, hot gases rise quickly and disperse into the workspace. Professional extraction solutions use high-efficiency filtration to immediately trap contaminants before they become airborne hazards. Systems designed for industrial environments offer targeted airflow and advanced filtration to eliminate particles that standard ventilation cannot capture.

Setting up a laser cutter exhaust system significantly reduces exposure to harmful emissions and supports manufacturing standards by ensuring that air quality remains within regulatory limits.

Enhancing Precision and Equipment Performance

High-precision manufacturing depends on the stability and longevity of machinery. Laser optics and internal components are highly sensitive to debris accumulation. Particulates from cutting operations can settle onto lenses and mirrors, resulting in decreased cutting accuracy and frequent maintenance interventions.

Why Extraction Improves Operational Efficiency

Fume extractors help preserve machine integrity by preventing buildup. Clean air facilitates optimal laser performance, consistent beam quality, and extended equipment lifespan. This decreases downtime, allows uninterrupted production, and reduces the long-term cost of ownership for industrial equipment.

Protecting Workforce Health

Employee well-being plays a direct role in productivity. Inhaling laser cutting fumes can cause respiratory irritation, eye discomfort, and long-term pulmonary complications. Employers who prioritize fume control demonstrate commitment to workplace safety while aligning with industry compliance requirements.

A Proactive Approach to Compliance

Advanced extraction systems are designed to meet occupational safety standards, helping organizations avoid regulatory citations and penalties. Beyond compliance, cleaner air fosters a more comfortable work environment, contributing to higher morale and increased operational performance.

Supporting Scalability and Innovation

As industries evolve toward automation and high-volume production, scalable air filtration becomes indispensable. Laser cutter fume extractors are engineered to adapt to different materials, production levels, and facility layouts, ensuring consistent air purification regardless of operational demands.

Future-Ready Air Quality Management

Manufacturers adopting advanced extraction technologies are better positioned to implement new production capabilities. Whether integrating robotics, expanding throughput, or introducing new materials, a stable atmospheric environment ensures reliable results across every application.

Conclusion

High-precision manufacturing demands an uncompromising standard of air quality and equipment protection. Laser cutter fume extraction systems are not just supportive tools; they are essential to ensuring consistent performance, safeguarding workforce health, and maintaining a competitive edge in production environments. By controlling emissions at the source, manufacturers can secure cleaner air, superior output quality, and enduring operational stability.