The Evolution and Impact of Pigging Application Across Modern Industries

In today’s industrial landscape, efficiency, hygiene, and sustainability are no longer luxuries—they are essential. One proven technology that enables these goals across multiple sectors is pigging. While the term may sound unconventional, a pigging application refers to an advanced method of pipeline maintenance, product recovery, and cleaning using a specialized device known as a pig.

Though originally developed for cleaning large oil pipelines, pigging technology has rapidly evolved and diversified. Today, it is widely used in industries such as food and beverage, cosmetics, pharmaceuticals, paints, chemicals, and even biotechnology. In this article, we explore the origins, functionality, and cross-sector benefits of pigging, shedding light on why the right pigging application is a strategic asset in any high-performance production environment.

What Is a Pigging Application?

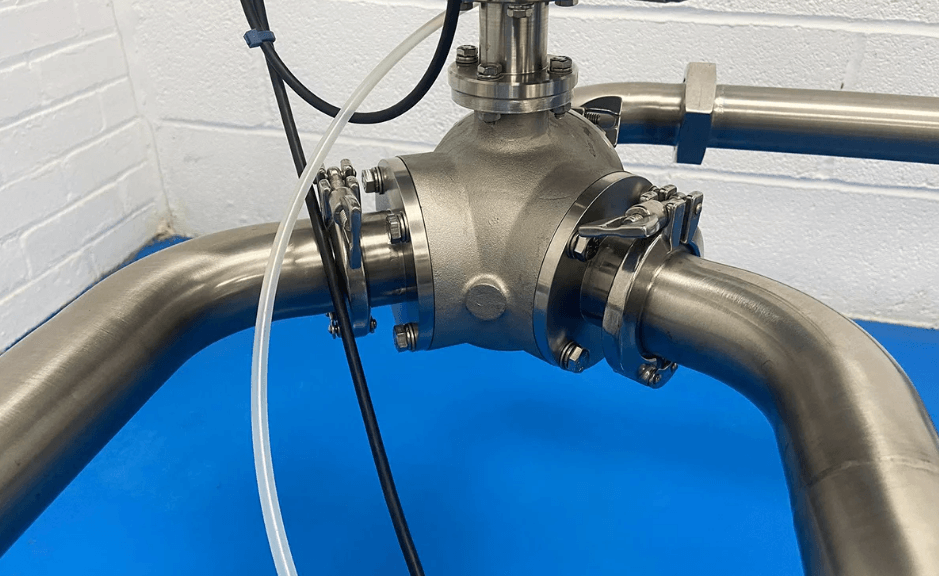

A pigging application involves inserting a cylindrical device—called a pig—into a pipeline to perform specific functions such as pushing residual product out, cleaning pipe walls, or separating product batches. The pig is propelled using compressed air, nitrogen, water, or other fluids, and is typically made of durable, hygienic, and chemically resistant materials like silicone, polyurethane, or rubber.

Pigging systems are automated or semi-automated and include launch stations, receivers, sensors, and control units. Depending on the industry, a pigging application might serve multiple purposes—cleaning, product recovery, line clearance, or even pipeline inspection.

Origins: Pigging in Oil and Gas

The term “pigging” is believed to have originated from the squealing sound early devices made as they moved through the pipeline. Initially used in the oil and gas industry, pigs were designed to remove wax, debris, and sediment from inside long pipelines.

Today, pigging remains a critical process in petroleum transport, where intelligent pigs fitted with sensors are also used to assess pipeline integrity, detect corrosion, and monitor pressure variations. These intelligent pigging applications have become crucial to the safety and efficiency of energy infrastructure.

See also: How Emerging Tech Will Reshape Education by 2030

Modern Pigging Application in Manufacturing

As industrial processing grew more complex and hygiene-focused, pigging systems were adapted for modern manufacturing lines. Let’s explore how various sectors benefit from a suitable pigging application.

1. Food and Beverage Industry

In food processing, where product purity and hygiene are paramount, pigging is indispensable.

Common applications include:

Recovering sauces, dairy products, syrups, or chocolate left in transfer lines

- Minimizing flavor carryover between batches (e.g., orange juice to mango juice)

- Reducing water and chemical usage during cleaning cycles

- Enhancing CIP (clean-in-place) efficiency

A properly implemented pigging application in this sector can recover up to 99.5% of the product, reduce cleaning time by 70%, and boost overall profitability.

2. Cosmetics and Personal Care

Cosmetic manufacturers often produce various viscous and high-value products like creams, lotions, body gels, and shampoos. A tailored pigging application helps:

Eliminate cross-contamination between formulations

- Increase product yield by recovering leftover product

- Cut cleaning time, especially for fragrance-heavy or sticky substances

This not only saves money but ensures regulatory compliance in cleanliness and product labeling.

3. Paints, Coatings, and Inks

This industry faces similar challenges in batch changeovers and cleaning complexity. Paints are typically thick and prone to residue buildup.

Pigging applications here are used to:

Clean pipelines between color changes

- Recover expensive coatings and pigments

- Prevent chemical reactions between different formulations

- Reduce VOC emissions by using fewer solvents for cleaning

Paint manufacturers employing pigging can avoid wasting tens of gallons per batch, translating into major cost and environmental savings.

4. Pharmaceuticals and Biotechnology

With the need for aseptic, highly controlled environments, pigging in pharma is carefully engineered for safety and compliance.

Pigging application advantages include:

Enhancing batch integrity

- Avoiding contamination between active pharmaceutical ingredients (APIs)

- Meeting strict documentation and traceability standards

- Streamlining cleaning validation and sterilization

From oral suspensions to topical gels, pharma-grade pigging supports GMP (Good Manufacturing Practices) and operational excellence.

5. Chemical Manufacturing

Whether handling acids, solvents, adhesives, or polymers, chemical manufacturers leverage pigging for safe product handling and waste reduction.

Key uses of pigging applications include:

Reducing operator exposure to hazardous chemicals

- Lowering disposal costs of contaminated cleaning fluids

- Improving yield on high-cost formulations

- Managing batch separations within shared pipelines

Given the rising cost of raw materials and stricter environmental regulations, the chemical industry sees pigging as both a safety measure and a profitability booster.

Environmental and Financial Benefits

Pigging applications don’t just streamline operations—they offer tangible environmental and financial returns.

✅ Reduced Product Loss

Each batch produces leftovers in pipelines. Pigging enables nearly full recovery, maximizing sellable product and reducing waste.

✅ Less Water and Chemicals

By removing most of the product prior to cleaning, less rinsing is required. This conserves water and lowers effluent treatment costs.

✅ Shorter Downtime

Changeovers between different products are faster with pigging, increasing plant uptime and production throughput.

✅ Better Sustainability Metrics

Pigging aligns with ISO 14001, ESG goals, and corporate sustainability mandates. It decreases carbon footprint and resource consumption.

Choosing the Right Pigging Application

Not all pigging systems are the same. The right pigging application depends on factors like:

Pipeline diameter and length

- Product viscosity and temperature

- Hygiene or chemical compatibility requirements

- Frequency of changeovers

- Automation level preferred

Modern systems often include programmable logic controllers (PLCs), sensors for pig tracking, automated launching and receiving, and safety interlocks.

Misconceptions About Pigging Applications

“It’s only useful in large factories.”

False. Small and mid-sized facilities also benefit, particularly when working with expensive products or small batches.

“Installation disrupts current operations.”

With the right vendor and planning, pigging can be retrofitted with minimal downtime.

“Pigging is just for cleaning.”

Pigging is also used for product recovery, separation, quality assurance, and inspection—making it a multipurpose solution.

Real-World Case Study: Pigging Success in Action

A UK-based cosmetic manufacturer producing 10 types of shampoo and lotion deployed a pigging application to recover product from transfer lines between blending tanks and filling stations.

Before pigging:

8 liters of product lost per line per batch

- 30-minute water flush cycle

- Frequent contamination issues during changeovers

After pigging:

Less than 1 liter of loss per line

- Cleaning time cut to 10 minutes

- 95% less water used per rinse

- ROI achieved in 7 months

This example illustrates the measurable impact of even a basic pigging application in a dynamic manufacturing environment.

Final Thoughts

Pigging applications are no longer niche or industry-specific—they are widespread, adaptable, and essential tools in modern production. Whether your goal is to increase product yield, reduce waste, improve hygiene, or lower operational costs, a well-designed pigging application delivers reliable and repeatable results.

From high-viscosity chocolate to corrosive chemicals, there’s a pigging system out there to make your production leaner, greener, and more profitable.