Selecting the Right Warehousing Supplier: Key Factors to Consider

In today’s competitive supply chain landscape, warehouse partnerships can make or break business performance. Choosing the ideal warehousing supplier is a critical decision that directly impacts logistics efficiency, inventory accuracy, and overall supply chain performance. With market demands shifting rapidly and customer expectations rising, the role of warehousing extends far beyond storage. It’s now about timely fulfilment, seamless integration, and scalable support. Understanding what to look for in a warehousing partner ensures long-term operational success.

Facility Capabilities and Infrastructure

The first thing to evaluate is whether the warehousing facility can accommodate your business’s current and future needs. Consider square footage, ceiling height, loading dock availability, and climate control. For businesses handling perishable or sensitive items, temperature-regulated storage becomes essential.

Beyond physical attributes, the warehouse layout also matters. Facilities designed with optimal racking systems, clear pathways, and efficient picking zones support faster handling times. It’s also important to ask about security measures such as surveillance systems, controlled access, and inventory monitoring protocols.

Having visibility into the critical importance of warehousing in supply chain management highlights how storage infrastructure affects timely delivery and risk mitigation across your operations.

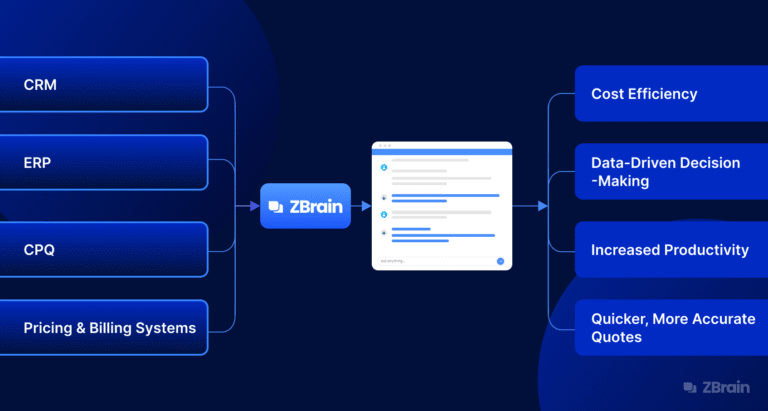

Technology Integration and Inventory Management

A modern warehousing supplier should offer robust inventory management systems. These systems should allow real-time tracking, order management, barcode scanning, and automated notifications. Integration with your existing enterprise resource planning (ERP) or e-commerce platforms ensures a smooth data flow, reducing manual errors and improving forecasting accuracy.

When evaluating potential suppliers, look for digital capabilities that enable transparency, such as cloud-based dashboards or automated reporting tools. This level of visibility helps manage reorder levels, track inbound and outbound shipments, and reduce stockouts or overstocking.

Technology also aids in identifying bottlenecks or inefficiencies that might not be visible through manual tracking methods. In the long run, it supports better decision-making and operational agility.

Scalability and Flexibility

Your warehousing needs may change with seasonal demand, market expansion, or product line diversification. A good warehousing supplier must be able to scale services without compromising performance. Ask whether they can accommodate increases in inventory volume, adjust labor capacity, or expand into additional storage zones if needed.

Flexibility also refers to handling multiple SKUs, bulk orders, or custom kitting requirements. A supplier that adapts to various fulfillment models, such as first-in-first-out (FIFO), cross-docking, or just-in-time (JIT), will better align with your logistics goals.

This adaptability is crucial for companies with complex supply chains or frequently shifting consumer behavior. Reliable warehousing partners contribute to operational continuity even in volatile conditions.

Location and Accessibility

The location of your warehousing supplier directly influences delivery timelines and shipping costs. Facilities situated near major transportation hubs, such as highways, ports, and airports, allow faster transit and easier carrier coordination. A centrally located warehouse also supports regional distribution strategies, helping reduce last-mile delivery delays.

When assessing location, also consider its proximity to your suppliers or manufacturing sites. This helps streamline inbound logistics and minimizes delays in restocking critical items. For e-commerce businesses, being closer to your customer base can offer a competitive edge by enabling same-day or next-day deliveries.

Compliance, Certifications, and Support

Warehousing operations must comply with industry regulations and safety standards. Depending on your sector, this could include food-grade certifications, hazardous material handling licenses, or ISO compliance. A supplier that follows regulatory best practices ensures that your goods are stored safely and legally.

Equally important is customer support. Your supplier should provide a dedicated point of contact, regular performance reviews, and clear escalation paths in case of service issues. Strong communication channels build trust and promote efficient problem resolution.

Conclusion

Choosing a warehousing supplier requires careful evaluation of facilities, technology, scalability, and service quality. The right partner not only stores your inventory but also enhances supply chain responsiveness and customer satisfaction. Prioritizing long-term compatibility and operational transparency ensures your warehousing function supports, rather than hinders, business growth.