Importance of Circuit Board Cleaning Machines in Modern Electronics

Understanding Circuit Board Cleaning Machines

Circuit boards are the foundation of virtually all electronic devices. Ensuring these boards remain free of dust, flux residues, oils, and other contaminants is critical for reliable performance. Circuit board cleaning machines are specialized equipment designed to clean boards effectively. By removing impurities, these machines help maintain signal integrity, prevent corrosion, and extend the lifespan of electronic products.

Benefits of Using Circuit Board Cleaning Machines

Enhancing Electrical Performance

Contaminants on circuit boards can lead to short circuits, increased resistance, and signal interference. Circuit board cleaning machines ensure that residues are thoroughly removed, which improves conductivity and maintains overall device efficiency.

Reducing Manufacturing Defects

Automated cleaning reduces human error, ensuring that each board is cleaned consistently. This minimizes production defects, reduces rework, and ensures higher quality control in manufacturing.

Supporting High-Speed Production Lines

Modern electronics production relies on automation. Circuit board cleaning machines can integrate into assembly lines, providing fast and efficient cleaning without slowing down manufacturing. This allows companies to maintain productivity while ensuring clean, high-quality boards.

Types of Circuit Board Cleaning Machines

Inline Cleaning Machines

Inline machines are part of continuous production lines. They clean boards as they move through the assembly process, offering high throughput and uniform cleaning. These systems often use spray-in-air, foam cleaning, or ultrasonic techniques.

Batch Cleaning Machines

Batch machines clean multiple boards simultaneously in a single chamber. They are ideal for smaller production runs, prototypes, or specialized boards. Batch cleaning offers flexibility and thorough cleaning but may operate slower than inline systems.

Ultrasonic Cleaning Machines

Ultrasonic machines generate high-frequency sound waves in cleaning solutions, producing microbubbles that remove residues from even the smallest crevices. This method is especially effective for densely populated or delicate circuit boards.

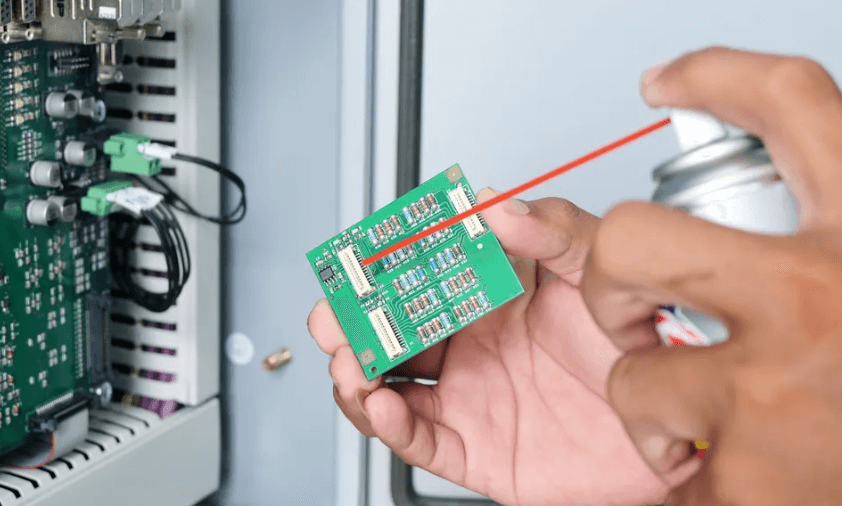

Foam and Spray-in-Air Systems

Foam and spray-in-air machines apply cleaning solutions directly onto circuit boards. These methods reduce chemical usage while maintaining effective cleaning, making them environmentally friendly and cost-efficient.

See also: Can Tech Solve the Climate Crisis?

Key Features of Modern Circuit Board Cleaning Machines

Precision and Consistency

Modern machines clean boards uniformly, preventing circuit board cleaning machine damage to components. Automated controls and sensors ensure that each board receives the same level of cleaning, maintaining quality across production.

Compatibility with Different PCB Types

Circuit board cleaning machines can handle single-sided, double-sided, and multilayer boards. They are designed to work with various component sizes and layouts, providing versatility for different electronic devices.

Eco-Friendly Operation

Many machines are designed to use less water and biodegradable cleaning solutions. Recycling systems and energy-efficient designs reduce environmental impact without compromising cleaning performance.

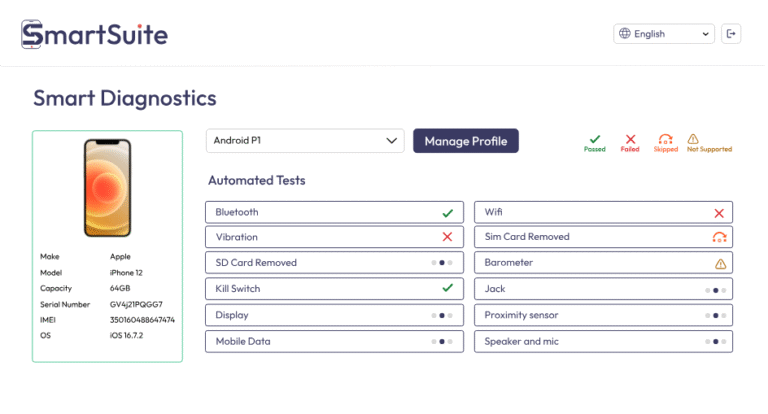

Integration with Inspection Systems

Advanced machines integrate with automated inspection systems to verify cleanliness levels. This ensures boards meet industry standards before moving to the next production stage.

Applications in Various Industries

Consumer Electronics

Phones, laptops, and other consumer electronics rely on clean circuit boards for reliable performance. Circuit board cleaning machines ensure high-quality boards for durable and efficient devices.

Automotive Electronics

Automotive electronic systems face high temperatures, vibrations, and environmental challenges. Properly cleaned boards ensure reliable performance and longevity in vehicles.

Medical Devices

Medical equipment requires extremely clean boards to function safely. Circuit board cleaning machines remove residues that could interfere with critical electronics in devices like monitors, imaging machines, and implants.

Industrial Equipment

Industrial controllers, robotics, and automation systems require reliable PCBs. Cleaning machines protect these boards from contaminants that could cause malfunctions and downtime.

Advantages of Investing in Circuit Board Cleaning Machines

Lower Failure Rates

By removing contaminants, these machines reduce the likelihood of electrical failures and rework, improving reliability and product quality.

Higher Manufacturing Efficiency

Automation in cleaning reduces manual labor, increases production speed, and ensures consistent results. Companies benefit from faster production while maintaining board quality.

Compliance with Industry Standards

Industries such as automotive, aerospace, and medical require boards to meet strict cleanliness standards. Circuit board cleaning machines help manufacturers comply with IPC, ISO, and other regulatory guidelines.

Improved Product Quality

Clean boards allow for better soldering, reduced signal interference, and enhanced overall performance. High-quality circuit boards result in superior electronic products.

Challenges and Considerations

Handling Sensitive Components

Modern PCBs contain smaller and more delicate components. Cleaning machines must remove residues without causing damage. Advanced systems are designed to balance thorough cleaning with component safety.

Chemical Management

Selecting appropriate cleaning solutions is crucial. Machines must minimize chemical usage while maintaining effective cleaning to reduce environmental impact.

Balancing Speed and Quality

High-speed production should not compromise cleaning quality. Modern machines optimize throughput while ensuring consistent, precise cleaning.

Future Trends in Circuit Board Cleaning Technology

Integration with AI and Automation

Artificial intelligence helps monitor cleaning quality, predict maintenance needs, and adjust parameters automatically for different PCB types. This enhances precision and reduces manual oversight.

Environmentally Sustainable Practices

Future cleaning machines will increasingly use eco-friendly solvents, recycle water, and reduce energy consumption, supporting sustainable manufacturing processes.

Smart Factory Integration

Circuit board cleaning machines are becoming part of smart factories, providing real-time data on cleanliness, production efficiency, and maintenance requirements.

Advanced Inspection Systems

Next-generation machines will use AI-powered vision systems to detect microscopic residues, ensuring that all boards meet the highest cleanliness and quality standards.

Conclusion

Circuit board cleaning machines play a critical role in modern electronics manufacturing. They ensure consistent cleaning, improve reliability, support high-speed production, and help maintain compliance with industry standards. Investing in advanced circuit board cleaning technology enhances product quality, reduces failure rates, and increases efficiency across diverse industries. As electronics evolve, these machines will continue to be essential for producing high-performance, durable, and reliable electronic devices.